Thermoelectric module, Peltier module (also known as thermoelectric cooling modules, TEC) are a typical technology that utilizes the Peltier effect to achieve cooling in automotive refrigerators, car cooler. The following are the main application features, advantages, limitations, and development trends of these sheets in automotive refrigerators:

1. Working Principle Overview

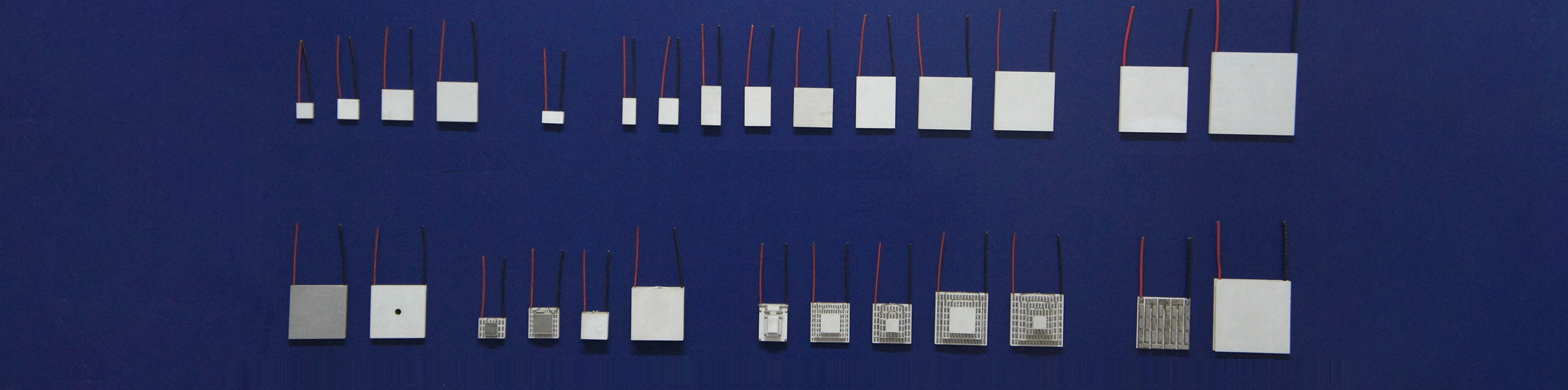

Thermoelectric cooling module, peltier module, peltier element is composed of N-type and P-type semiconductor materials. When a direct current is applied, a temperature difference is generated at the junction: one side absorbs heat (cold end), and the other side releases heat (hot end). By designing a reasonable heat dissipation system (such as fans, heat sinks), the heat can be expelled, thereby achieving cooling inside the refrigerator.

2. Advantages in Automotive Refrigerators, thermoelectric car coolers, wine coolers, beer coolers,beer chills

No compressor, no refrigerant

No use of traditional refrigerants such as Freon, environmentally friendly and without leakage risks.

Simple structure, no moving parts, quiet operation, and low vibration.

Small size, light weight

Suitable for space-constrained vehicle environments, facilitating integration into small vehicle refrigerators or cup holder cooling devices.

Fast startup, precise control

Power on for cooling, with fast response; temperature can be precisely controlled by adjusting the current size.

High reliability, long lifespan

No mechanical wear, average lifespan can reach tens of thousands of hours, low maintenance costs.

Supports both cooling and heating modes

Changing the current direction can switch the cold and hot ends; some vehicle refrigerators have heating functions (such as keeping coffee warm or heating food).

3. Main Limitations

Low cooling efficiency (low COP)

Compared to compressor refrigeration, the energy efficiency is relatively low (usually COP < 0.5), high power consumption, not suitable for large-capacity or deep-freezing requirements.

Limited maximum temperature difference

The maximum temperature difference of a single-stage TEC, single stage thermoelectric cooling module is approximately 60–70°C. If the ambient temperature is high (such as 50°C in a vehicle during summer), the lowest temperature at the cold end can only drop to around -10°C, making it difficult to achieve freezing (-18°C or below).

Dependence on good heat dissipation

The hot end must have effective heat dissipation; otherwise, the overall cooling performance will sharply decline. In a hot and enclosed vehicle compartment, heat dissipation is difficult, limiting performance.

High cost

High-performance TEC modules ,high performance peltier device, and accompanying heat dissipation systems are more expensive than small compressors (especially in high-power scenarios).

4. Typical Application Scenarios

Small vehicle refrigerators (6–15L): used for refrigerating beverages, fruits, medicines, etc., maintaining 5–15°C.

Vehicle cold and warm boxes: have both cooling (10°C) and heating (50–60°C) functions, suitable for long-distance driving.

Original equipment configuration for high-end vehicles: some models of Mercedes-Benz, BMW, etc., are equipped with TEC refrigerators as comfort features.

Camping/outdoor power refrigerator: used with vehicle power or mobile power supply, portable.

5. Technological Development Trends

Research on new thermoelectric materials

Optimization of Bi₂Te₃-based materials, nanostructured materials, Skutterudites, etc., to increase ZT value (thermoelectric efficiency), improving efficiency.

Multi-stage thermoelectric cooling systems

Series connection of multiple TECs to achieve larger temperature differences; or combined with phase change materials (PCM) to improve insulation performance and reduce power consumption.

Intelligent temperature control and energy-saving algorithms

Real-time power regulation through sensors + MCU to extend range (especially important for electric vehicles).

Deep integration with new energy vehicles

Utilizing the power supply advantages of high-voltage platforms to develop efficient vehicle cold and warm boxes to meet users’ demands for comfort and convenience.

6. Summary

Thermoelectric cooling modules, TEC modules, Peltier modules are suitable for small-capacity, mild cooling, quiet, and environmentally friendly application scenarios in automotive refrigerators. Although limited by energy efficiency and temperature difference, they have irreplaceable advantages in specific markets (such as high-end passenger cars, camping equipment, medical cold chain transportation assistance). With the advancement of materials science and thermal management technology, their application prospects will continue to expand.

TEC1-13936T250 Specification

Hot side temperature is 30 C,

Imax:36A,

Umax: 36.5 V

Qmax:650 W

Delta T max:> 66C

ACR: 1.0±0.1mm

Size: 80x120x4.7±0.1mm

TEC1-13936T125 Specification

Hot side temperature is 30 C,

Imax: 36A,

Umax: 16.5V

Qmax:350W

Delta T max: 68 C

ACR:0.35 ±0.1 Ω

Size : 62x62x4.1±0.1 mm

TEC1-24118T125 Specification

Hot side temperature is 30 C,

Imax: 17-18A

Umax: 28.4V

Qmax:305 +W

Delta T max: 67 C

ACR:1.30Ohm

Size : 55x55x3.5+/_ 0.15mm

Post time: Jan-30-2026