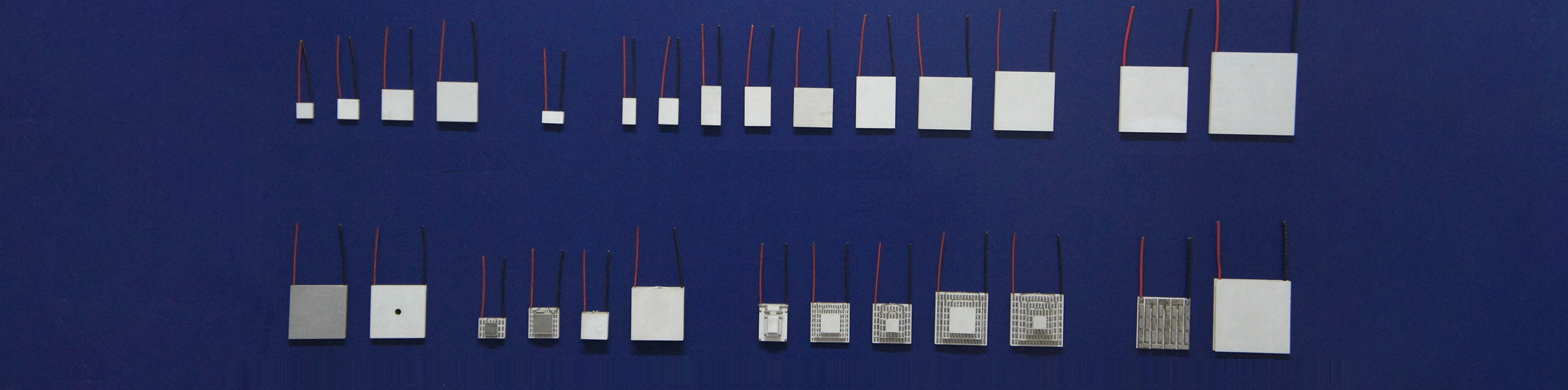

Thermoelectric cooling modules,Thermoelectric module ,TEC module ,peltier device Installation method

There are generally three ways to install thethermoelectric module welding, bonding, bolt compression and fixing. In the production of which method of installation, according to the requirements of the product to determine, in general, for the installation of these three kinds of, first of all to use anhydrous alcohol cotton will be thethermoelectric cooler parts of the two sides surface clean, cold plate and cooling plate installation surface should be processed, surface flatness is not greater than 0.03mm, and clean, the following is the three kinds of installation of the operation process.

1. Welding.

The installation method of welding requires that the outer surface of theTEC module must be metallized, and the cold plate and the cooling plate must also be able to solder (such as: copper cold plate or cooling plate). When installing the cold plate, cooling plate and peltier device ,peltier element, thermoelectric cooling modules,TEC module, the cold plate and thermoelectric cooling plate are heated first, (the temperature and the melting point of the solder are similar), the low-temperature solder between about 70 ° C and 110 ° C is melted on the installation surface. Then the hot surface of the peltier device, peltier module,Thermoelectric module , TEC device and the mounting surface of the cooling plate, the cold surface of the thermoelectric module,thermoelectric device and the mounting surface of the cold plate are in parallel contact and rotating extrusion to ensure that the working surface is in good contact after cooling. The installation method is more complex, not easy to maintain, and is generally used in special occasions.

2. Glue.

The adhesive installation method is to use an adhesive with good thermal conductivity, evenly coated on the installation surface of the Thermoelectric cooling module,, cold plate and cooling plate. The thickness of the adhesive is 0.03mm, the cold and hot surface of the peltier device , peltier cell,TEC module, thermoelectric module and the installation surface of the cold plate and the heat dissipation plate are extruded parallel, and the gently rotated back and forth to ensure the good contact of the contact surface, and the ventilation is placed for 24 hours to cure naturally. The installation method is generally used to permanently fix the thermoelectric cooling device,peltier cell ,thermoelectric cooling device,to the place of the heat dissipation plate or cold plate.

3. Compression and fixing of stud.

The installation method of compression fixing of the stud is to evenly coat the installation surface of the peltier modulecold plate and heat dissipation plate with a thin layer of thermal silicone grease, the thickness of which is about 0.03mm. Then the hot surface of thepeltier cooler and the installation surface of the cooling plate, the cold surface of the peltier devices,thermoelectric cooling modules and the installation surface of the cold plate are in parallel contact, and gently rotate the TEC module,thermoelectric module’s back and forth, extrude excessive thermal grease, be sure to ensure that the working surface is in good contact, and then tighten between the cooling plate, the Thermoelectric module,Peltier module,TEC module,thermoelectric cooling module and the cold plate with screws, the fastening force should be uniform, not excessive or too light. The heavy is easy to crush the refrigerator, and the light is easy to cause the working face to not contact. The installation is simple, fast, easy maintenance, high reliability, is currently the most used in the product application of one of the installation methods.

The above three installation methods in order to achieve the best cooling effect, the application of insulation material between the cold plate and the cooling plate, the application of heat insulation washer, in order to reduce hot and cold alternations, the size of the thermoelectric cooling cold plate and the cooling plate depends on the cooling method and cooling power size, according to the application situation.

thermoelectric cooling module TES1-01009LT125 Specification

Imax:0.9A,

Umax: 1.3V

Qmax:0.65W

Delta T max: 72C

ACR: 1.19﹢/﹣0.1Ω

Size: 2.4×1.9×0.98mm

Round and center hole thermoelectric module TES1-13905T125 Specification

Hot side temperature is 25 C,

Imax: 5A,

Umax:15-16 V

Qmax:48W

Delta T max: 67 C

Height: 3.2+/- 0.1mm

Size :Outer diameter : 39+/- 0.3mm, Inner diameter : 9.5mm +/- 0.2mm,

22AWG PVC Cable Wire Length: 110mm +/- 2mm

thermoelectric module TES1-3202T200 Specification

Imax:1.7-1.9A,

Umax: 2.7V

Qmax:3.1W

Delta T max: 72C

ACR: 1.42-1.57Ω

Size: 6×8.2×1.6-1.7mm

Post time: Nov-28-2024